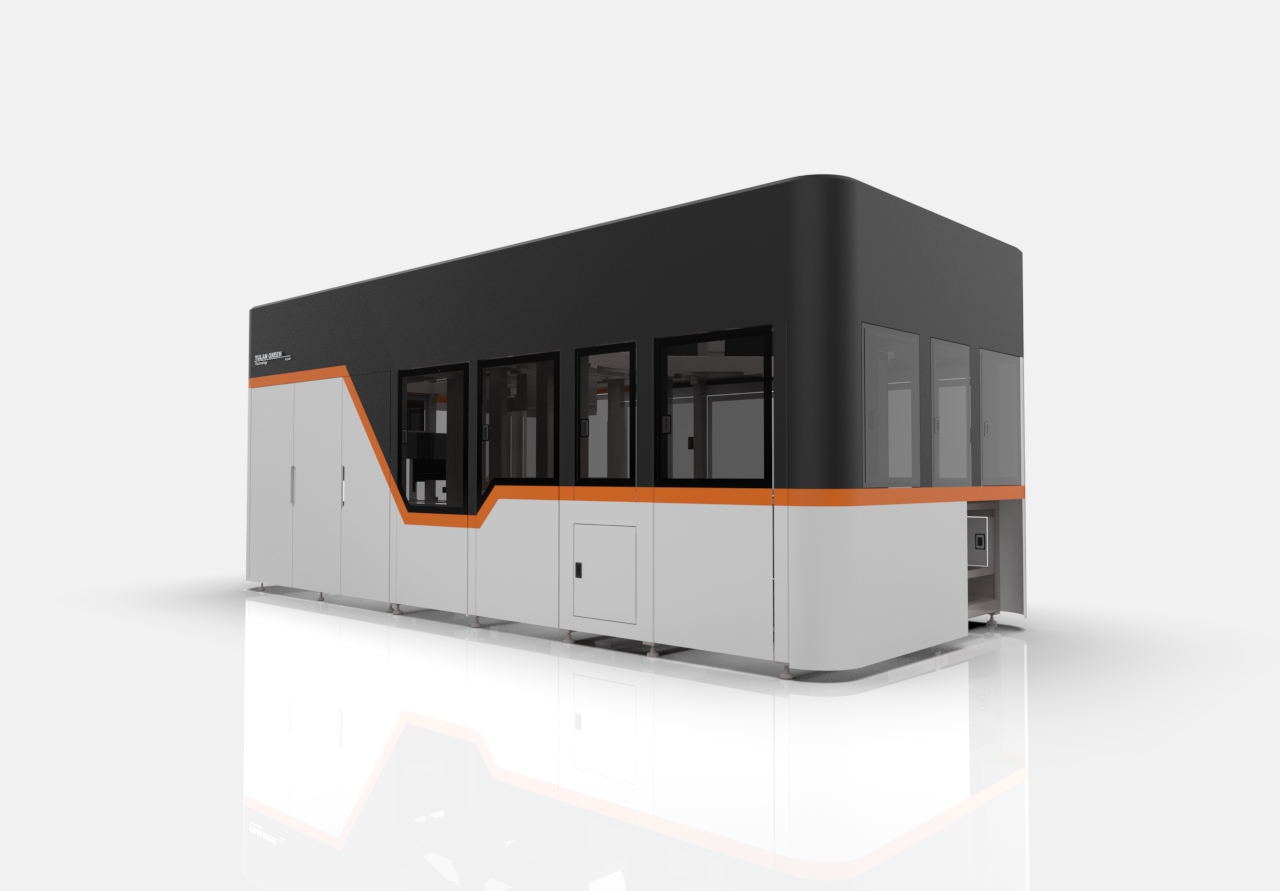

紙塑生產工具機外殼設計

此專案為一款整合 紙塑成型全流程 的大型工具機外殼設計。內部結合自動化生產與 AI 智能管理,能從原料進料、成型到成品輸出,完整涵蓋紙塑生產線。

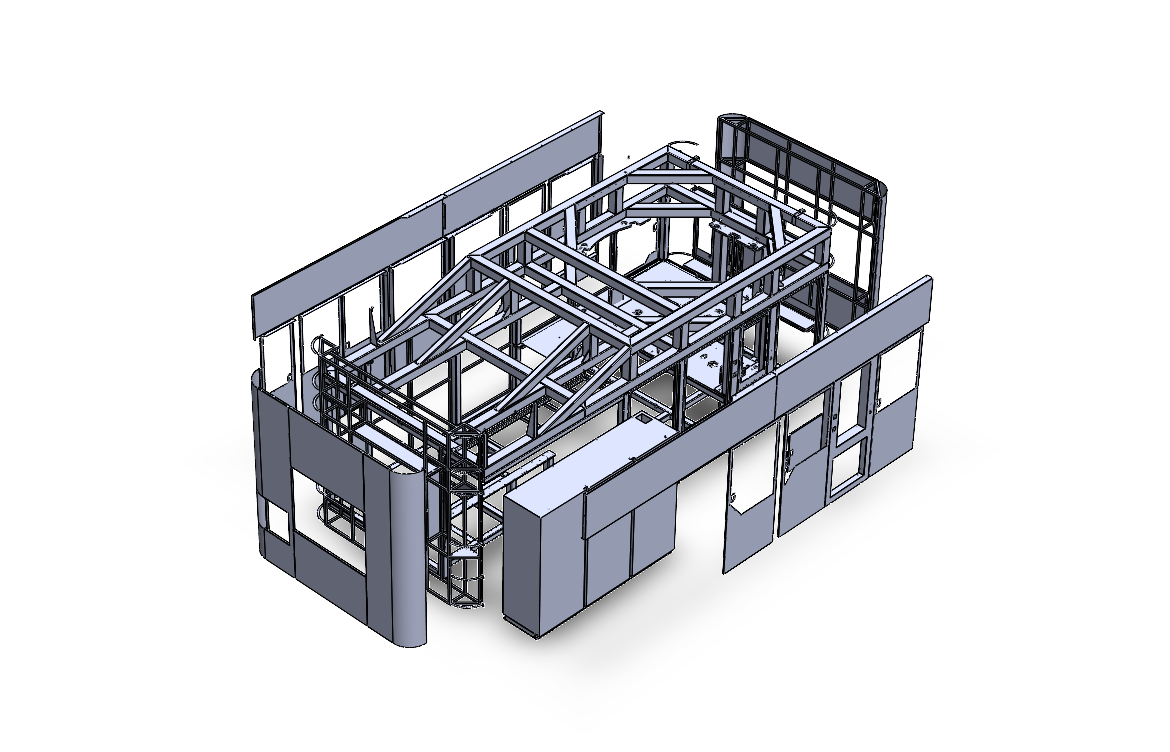

在設計外殼時,我們以「高效、安全、低人力」為核心思維。透過模組化結構與清晰的動線規劃,外殼不僅提供直觀的操作平台,也降低人力需求,使工作人員能以最少人力完成流程監控與操作。

此外,維護與保養的便利性亦被納入設計考量。外殼門板與檢修口的位置經過精密規劃,讓技術人員能快速進出關鍵區域,縮短維護時間並提升生產穩定性。外殼邊角與結構亦兼顧人員安全,確保在操作過程中避免潛在風險。

整體外觀以簡潔俐落的幾何語彙呈現,搭配明確的色帶區隔機能區域,強化辨識度與企業識別。此設計不僅是外觀包覆,更是生產流程與人機互動的最佳化平台,體現 設計與工業效率並行 的價值。

Pulp Molding Machine Enclosure

This project focuses on the enclosure design of a large-scale machine that integrates the entire pulp molding production process. Inside, the system combines automated production with AI management, covering everything from raw material input to molding and finished product output.

The enclosure design centers on the principles of efficiency, safety, and minimal manpower. Through modular structures and well-planned workflows, the exterior provides an intuitive operating platform while reducing labor requirements, enabling operators to manage and monitor the process with ease.

Maintenance and servicing were also key considerations. Access doors and inspection points are strategically positioned to allow technicians to quickly reach critical areas, minimizing downtime and ensuring production stability. Rounded edges and structural safety measures further protect workers during operation.

Visually, the enclosure adopts clean geometric forms, accented with bold color bands to distinguish functional zones and strengthen brand identity. Beyond simply housing the machine, the design serves as an optimized interface between production flow and human interaction, embodying the value of merging design with industrial efficiency.